HYFA

New methodologies for diagnosis, fault tolerance and predictive maintenance through hybrid techniques and systems, DPI2008-01996.

Project Objectives

Summary

One way to increase the reliability of a system/process is based on including fault tolerance mechanisms that will allow system/process operation, even after the appearance of the fault may be with a degraded performance. For this reason there is in the industry (especially in critical applications) an increasing need and interest in developing control system that can operate systems/process in faulty conditions in an acceptable way. This type of control systems are known as fault-tolerant controllers (FTC).

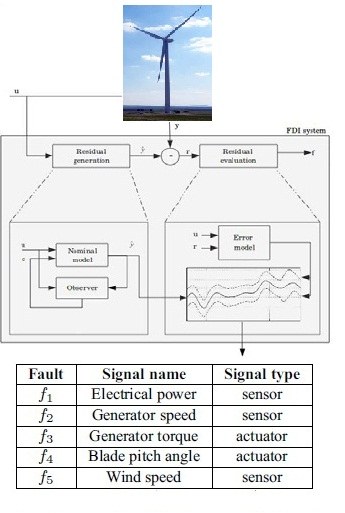

A fault can be viewed as a discrete event affecting the system by changing some of its particular properties (either the structure, the parameters, or both of them). Then, in turn, an active FTC should detect and isolate the fault and, if possible, estimate its magnitude (fault diagnosis) through the FDI module, and adapt the controller to the faulty situation such that the control objectives could be satisfied even in the fault presence (control re-design). A FTC system can be considered as an hybrid system if the discrete event nature of the fault occurrence and the controller re-design actions are taken into account, what makes not trivial its analysis and design. So far, the hybrid nature has been traditionally neglected in order to facilitate a simple design, reliable implementation, and systematic testing. Therefore, the analysis and design of fault-tolerant controllers require the use of techniques that are being developed for hybrid systems.

Another way to increase the system reliability is through the use of predictive maintenance. The purpose of predictive maintenance is to predict required schedules of maintenance by using sensitive measures of changes and faults in the system. The idea is to provide greater plant availability and economy, estimate the residual plant lifetime, calculate the accumulated wear (e.g. for mechanical/mechatronic systems) and detect incipient (hard to detect) faults. To achieve these goals, model-based fault diagnosis capable of dealing with incipient faults and reliability analysis methods will be used.

There are several reasons for using hybrid systems and methods on researching new methods for diagnosis, fault-tolerant control and predictive maintenance:

-

Since real industrial systems and processes are complex and because of such complexity prone to faults, there is an increasing concern about plant reliability and availability. Enhanced plant reliability and availability can be achieved by early diagnostic of system anomalies, combined with fault-tolerant control strategies and/or real-time predictive maintenance. Therefore, is important to deal with all three aspects in an integrated way.

-

A fault tolerant control system with predictive maintenance needs a good real-time diagnoser. Integrating information from multiple sources (system/signal models, time/frequency domains) is of capital importance when building a diagnoser in industry that is able to deal with incipient faults.

-

Fault tolerant control and diagnostic systems combine both discrete (logic) and continuous dynamics. Moreover, faults induce new modes in the monitored plant. For both reasons hybrid systems methodologies will be suitable to analyze and design fault tolerant and diagnosis systems.

-

A good diagnoser as well as a good fault-tolerant controller needs a good model aimed to fault diagnosis that is a model including intrinsic and faulty modes. So, system identification algorithms for fault diagnosis that are able to identify hybrid models (namely, those with multiple operating modes) using time/frequency-based models should provide the nominal model plus a bound for the modelling uncertainty in order to be useful for fault diagnosis and fault tolerant control.

The main purpose of this project fits completely within the research agenda in the Systems Control field of the FP7 of the European Union, since one of its priorities is established as the development of complex autonomous systems, with increased safety, dependability, and availability.

Four workpackages have been selected to fulfil the main goal. They are linked to several open research issues in the fault diagnosis and the fault tolerant control fields, which currently are limiting the application of these methodologies in real processes or systems.

Main workpackages

- Development of new identification algorithms focused on fault diagnosisn. These algorithms will provide signal or system models, in the time or frequency domains, and will be based on experimental process data. Hybrid systems methodologies will be used, because these models must take into account different working operation modes (correct or faulty ones)

- Development of new real-time fault diagnosis algorithms, using also hybrid systems methodologies. The algorithms must take into account information from multiple sources (signal analysis, or model-based estimations; time or frequency domains). Besides, they must integrate continuous dynamic information coming from fault detection along with discrete-event dynamic information coming from the fault isolation procedure (residual activation order, activation time, residual magnitude and sensibility).

- Development of new fault tolerant mechanisms – virtual sensors and actuators- to guarantee the global performance of the system –in terms of stability, reliability, safety, and availability- even after fault occurrence. Moreover, these mechanisms must integrate results from predictive maintenance tools. Hybrid systems methodologies will also be used to accomplish the fault tolerant system design, due to the inherent hybrid system nature of this kind of systems.

- Integration of the newly developed methodologies, and their application and validation on different processes and systems: inherited from previous projects of the applicant group (fuel-cell system), to be acquired (gas turbine), and real process/systems (drinking water networks, sewer 2 networks, or elevators) provided by several companies: AGBAR, CLABSA, and ORONA, respectively. The applicant group has strong expertise in the model-based fault diagnosis and fault tolerant control research fields, and in the proposed application areas.

Most relevant publications

- C. Ocampo-Martinez and V. Puig, “Fault Tolerant Model Predictive Control in the Hybrid Systems Framework: Application to Sewer Networks”, International Journal of Adaptive Control and Signal Processing. Vol. 23 (8), pp. 757-787, <Journal article at UPCommons>, 2009.

- T. Escobet, D. Feroldi, S. De Lira, V. Puig, J. Quevedo, J. Riera and M Serra, “Model-based fault diagnosis in PEM fuel cell systems”, Journal of Power Sources, 192, pp. 216-223, <doi:10.1016/j.jpowsour.2008.12.014>, 2009.

- J. Meseguer, V. Puig, T. Escobet and J. Saludes, “Observer gain effect in linear interval observer-based fault detection”, Journal of process control, 20 (8), pp. 944-956, <doi: 10.1016/j.jprocont.2010.06.017>, 2010.

- J. Meseguer, V. Puig and T. Escobet, “Fault Diagnosis Using a Timed Discrete-Event Approach Based on Interval Observers: Application to Sewer Networks”, IEEE Transactions on Systems Man and Cybernetics Part A-Systems and Humans, 40 (5), pp. 900-9116, <doi:10.1109/TSMCA.2010.2052036>, 2010.

- J. Quevedo, V. Puig, G. Cembrano, J. Blanch, J. Aguilar, D. Saporta, G. Benito, M. Hedo and A. Molina, “Validation and reconstruction of flow meter data in the Barcelona water distribution network”, Control Engineering Practice Journal, 18 (6), pp. 640-651, <doi:10.1016/j.conengprac.2010.03.003>, 2010.

Comparteix: