TIGER-SHEBA

Model Based Diagnosis of Gas Turbines. ESPRIT Trial Application: 27548, from 1998 to 2000.

Objectives

The main objective of the TIGER-SHEBA project is to develop a monitoring system with the following features:

- Monitor and supervise continuously the working conditions of a gas turbine.

- Early detect the occurrence of faults and problems.

- Do, as soon as possible, the accurate and correct diagnosis when a problem is detected.

Abstract

Gas turbines are the fundamental element in the energy generation industries. Today, new plants are built relatively fast and economical. In this increasingly competitive energy market, users need a number of requirements to be fulfilled:

- Gas turbines must operate continuously over long periods of time and with a minimal intervention of the operator.

- The cost derived from faults and problems maintenance must be reduced.

- Gas turbines can be supervised by operators that could be not very specialized and can be remotely controlled.

- The cost derived from faults and problems maintenance must be reduced.

- Gas turbines can be supervised by operators that could be not very specialized and can be remotely controlled.

To fulfil these requirements a supervising system that monitor and improve the availability of the plant avoiding downtime and unplanned system failures was needed. In case of a fault occurrence, the system must also minimize the time in which the system is shutdown.

The main requirement of the monitoring system is to detect problems at an early stage and to act before the fault becomes catastrophic for the turbine. If an unexpected fault occurs, the faulty component must be identified quickly reducing this way, the time to return to produce energy. Another factor to consider is that the efficiency of the machine has to be optimal. On average a machine consumes 1.5 million U.S. dollars in gas every month, so a drop in efficiency from 1 to 2% may represent a very expensive cost.

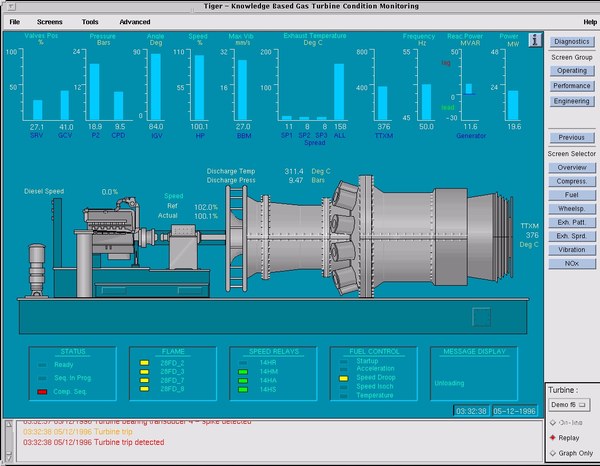

The TIGER-SHEBA monitoring system has been developed to fulfil these requirements. The system received around 600 measurements from the controller of the gas turbine at an interval time of 1 second, simultaneously the fault detection and diagnosis is realized over these data. The monitoring system incorporates a rules-based technique for fault detection in addition to a diagnosis system based on the combination of rules and hierarchical temporal abstraction. This methodology means that everything must be pre-programmed and therefore any new situation that has not been studied "a priori" and defined by a rule is an unknown situation and would be impossible to diagnose. For this reason a more advanced methodology (called second generation knowledge-based systems) using models representing the behaviour of the turbine for the diagnosis of the known and unknown discrepancies between the real system and the model has been incorporated.

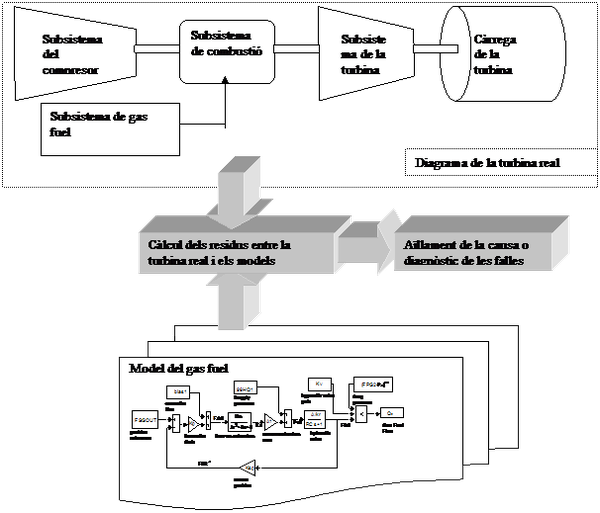

TIGER-SHEBA system incorporates models for fault detection and diagnosis, so that to compare at each instant the signals provided by sensors with the variables given by the models generating this way residuals or discrepancies between the real system and the models. In the case that no fault has occurred, the residuals are practically zero. In the contrary, if a fault or a malfunction of the turbine is detected the residuals will be different from zero.

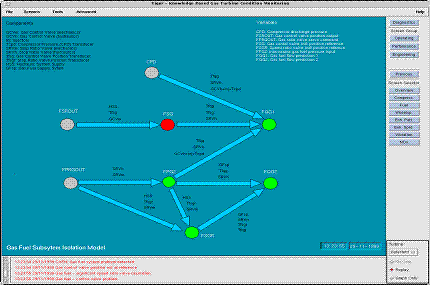

One of the main objective of this project has been the incorporation of qualitative interval models based on the Ca~En methodology. The integration of Ca~En software in TIGER-SHEBA have led to an innovative product for gas turbine monitoring and diagnosis.

The fault detection and diagnosis system was used on critical subsystems of several gas turbines such as the gas and liquid fuel supply systems. Figure shows the scheme of the fault isolation system for the liquid fuel supply. The isolation module of Ca~En generates diagnosis messages that are displayed in the TIGER diagnosis window .

The fault detection and diagnosis system was used on critical subsystems of several gas turbines such as the gas and liquid fuel supply systems. Figure shows the scheme of the fault isolation system for the liquid fuel supply. The isolation module of Ca~En generates diagnosis messages that are displayed in the TIGER diagnosis window .

Research Group

Joseba Quevedo*, Louise Travé-Massuyès**, Teresa Escobet* i Sebastian Tornil*

* Professors de la Universitat Politècncia de Catalunya.

** Directeur de Recherche du CNRS, membre of the Grup Diagnostic, Supervision et Conduite Qualitatifs” du LAAS-CNRS de Toulouse (França)

Main papers

- L. Travé-Massuyès, T. Escobet, R. Pons, S. Tornil, The Ca-En diagnosis system and its automatic modelling method, "Computación y sistemas", Octubre 2001, vol. 5, núm. 2, p. 128-143.

- T. Escobet, J. Quevedo, S. Tornil, L. Travé-Massuyès, Integration of Dynamic Models in a Gas Turbine Supervision Control, 7th IEEE International Conference on Emerging Technologies and Factory Automation ETFA '99. Barcelona, Oct. 1999.

- T . Escobet, L. Travé-Massuyès, S. Tornil, J. Quevedo, Fault detection of a gas turbine fuel actuator based on qualitative causal models, European Control Conference (ECC'01), Porto (Portugal), 4-7 Septembre 2001, 2741-2746.

- L. Travé-Massuyès, T . Escobet, R. Milne (2001a) Model-based diagnosability and sensor placement. Application to a frame 6 Gas turbine sub-system, 7th International Joint Conference on Artificial Intelligence (IJCAI'01), Seattle (USA), 4-10 Août 2001, pp.551-556 ; also in Proc. of 12th International Workshop on Principles of Diagnosis (DX'01), Sansicario, Via Lattea (Italie), 7-9 Mars 2001, pp.205-212.

Share: