HYFA_CAT

Projecte CICYT DPI2008-00403. Durada: 2009 -2011

HYFA: Noves metodologies de diagnòstic, tolerància a fallades i manteniment predictiu mitjançant tècniques i sistemes híbrids

OBJECTIUS

L'objectiu d'aquest projecte és:

RESUM

Tanmateix, els funcionaments defectuosos poden aparèixer provocant pèrdues econòmiques, averies a operadors i màquines, molèsties als usuaris, etc. A més, tot i que l'automatització que utilitza controladors de resposta ha evitat el funcionament manual de sistemes i processos, no els ha immunitzat contra els mal funcionament. En termes generals, una fallada és qualsevol canvi en el comportament de un component del procés / sistema. Ademés, un circuit tancat de control pot tant amplificar com amagar fallades, sense que puguin ser observades fins que causin la fallada del sistema / procés.

Una manera de fer crèixer la fiabilitat de un sistema / procés està basada en incloure mecanismes de tolerància a fallades, que permetin el funcionament de sistemes / processos, fins i tot després de l'aparició de l'averia, potser progressivament. Per aquest motiu hi ha (especialment en aplicacions crítiques) una necessitat i interés creixent en desenvolupar sistemes de control, que puguin fer funcionar de manera acceptable sistemes / processos defectuosos. Aquests sistemes de control són coneguts com controladors tolerants a fallades (FTC).

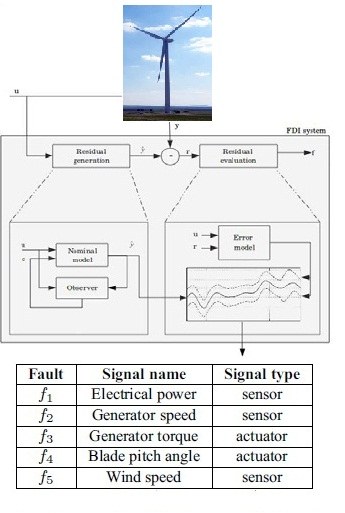

Una averia pot ser considerada com una prova discreta, que afecta el sistema canviant alguna de les seves propietats particulars (ja sigui l'estructura, els paràmetres o els dos). LLavors, a canvi, un FTC actiu hauria de detectar i aïllar la fallada i, si fos possible, calcular la seva magnitud (diagnosis de fallades), a través del mòdul FDI, i adaptar el controlador a la situació d'averia, de manera que l'objectiu de controlar pugui acomplir-se, fins i tot en el cas de fallada (redisseny de control). Un sistema FTC pot ser considerat com un sistema híbrid si es tenen en compte l'essència discreta de processos de l'averia i les accions de re-disseny del controlador, el que fa que el seu anàlisis i disseny no resultin trivials. Fins ara l'essència híbrida ha estat tradicionalment rebutjada, per tal de facilitar un disseny simple, una implementació fiable i un testatge sistemàtic. Per tant, l'anàlisis i disseny de controladors tolerants a fallades requereixen l'ús de tècniques que son desenvolupades per sistemes híbrids.

Una altra manera d'incrementar la fiabilitat del sistema és utilitzant el manteniment predictiu. L'objectiu del manteniment predictiu es predir un programa del manteniment necessari, utilitzant mesures susceptibles de canvis i fallades en el sistema. La idea és proporcionar una major disponibilitat de la planta i economia, estimar la vida útil residual de les instal · lacions, calcular el desgast acumulat (per exemple, per sistemes mecànics / mecatrònics) i detectar fallades incipients (difícils de detectar). Per assolir aquests objectius, s'utilitzaran el model basat en el diagnòstic de fallades, capaç de tractar amb fallades incipients i els mètodes d'anàlisi de fiabilitat.

There are several reasons for using hybrid systems and methods on researching new methods for diagnosis, fault-tolerant control and predictive maintenance:

-

Since real industrial systems and processes are complex and because of such complexity prone to faults, there is an increasing concern about plant reliability and availability. Enhanced plant reliability and availability can be achieved by early diagnostic of system anomalies, combined with fault-tolerant control strategies and/or real-time predictive maintenance. Therefore, is important to deal with all three aspects in an integrated way.

-

A fault tolerant control system with predictive maintenance needs a good real-time diagnoser. Integrating information from multiple sources (system/signal models, time/frequency domains) is of capital importance when building a diagnoser in industry that is able to deal with incipient faults.

-

Fault tolerant control and diagnostic systems combine both discrete (logic) and continuous dynamics. Moreover, faults induce new modes in the monitored plant. For both reasons hybrid systems methodologies will be suitable to analyze and design fault tolerant and diagnosis systems.

-

A good diagnoser as well as a good fault-tolerant controller needs a good model aimed to fault diagnosis that is a model including intrinsic and faulty modes. So, system identification algorithms for fault diagnosis that are able to identify hybrid models (namely, those with multiple operating modes) using time/frequency-based models should provide the nominal model plus a bound for the modelling uncertainty in order to be useful for fault diagnosis and fault tolerant control.

The main goal of this project is to develop a set of advanced tools for monitoring and supervision. These tools will provide better availability, dependability and safety conditions of industrial processes and/or systems, therefore improving their overall performance. To obtain these new tools, new methodologies must be developed, through the integration of fault diagnosis, fault tolerant techniques (fault tolerant control together with virtual sensors or actuators), and predictive maintenance. Fault tolerant techniques will increase the system safety and availability, once fault detection and diagnosis are performed. Moreover, predictive maintenance will increase the availability and dependability of the system, preventing fault appearance through a precise estimation of the remaining usable life-time in system components/processes.

The main purpose of this project fits completely within the research agenda in the Systems Control field of the FP7 of the European Union, since one of its priorities is established as the development of complex autonomous systems, with increased safety, dependability, and availability.

Four workpackages have been selected to fulfil the main goal. They are linked to several open research issues in the fault diagnosis and the fault tolerant control fields, which currently are limiting the application of these methodologies in real processes or systems.

Main workpackages

- Development of new identification algorithms focused on fault diagnosis. These algorithms will provide signal or system models, in the time or frequency domains, and will be based on experimental process data. Hybrid systems methodologies will be used, because these models must take into account different working operation modes (correct or faulty ones).

- Development of new real-time fault diagnosis algorithms, using also hybrid systems methodologies. The algorithms must take into account information from multiple sources (signal analysis, or model-based estimations; time or frequency domains). Besides, they must integrate continuous dynamic information coming from fault detection along with discrete-event dynamic information coming from the fault isolation procedure (residual activation order, activation time, residual magnitude and sensibility).

- Development of new fault tolerant mechanisms – virtual sensors and actuators- to guarantee the global performance of the system –in terms of stability, reliability, safety, and availability- even after fault occurrence. Moreover, these mechanisms must integrate results from predictive maintenance tools. Hybrid systems methodologies will also be used to accomplish the fault tolerant system design, due to the inherent hybrid system nature of this kind of systems.

- Integration of the newly developed methodologies, and their application and validation on different processes and systems: inherited from previous projects of the applicant group (fuel-cell system), to be acquired (gas turbine), and real process/systems (drinking water networks, sewer 2 networks, or elevators) provided by several companies: AGBAR, CLABSA, and ORONA, respectively. The applicant group has strong expertise in the model-based fault diagnosis and fault tolerant control research fields, and in the proposed application areas.

Projecte finanzat per:

Most relevant publications

- C. Ocampo-Martinez and V. Puig, “Fault Tolerant Model Predictive Control in the Hybrid Systems Framework: Application to Sewer Networks”, International Journal of Adaptive Control and Signal Processing. Vol. 23 (8), pp. 757-787, <Journal article at UPCommons>, 2009.

- T. Escobet, D. Feroldi, S. De Lira, V. Puig, J. Quevedo, J. Riera and M Serra, “Model-based fault diagnosis in PEM fuel cell systems”, Journal of Power Sources, 192, pp. 216-223, <doi:10.1016/j.jpowsour.2008.12.014>, 2009.

- J. Meseguer, V. Puig, T. Escobet and J. Saludes, “Observer gain effect in linear interval observer-based fault detection”, Journal of process control, 20 (8), pp. 944-956, <doi: 10.1016/j.jprocont.2010.06.017>, 2010.

- J. Meseguer, V. Puig and T. Escobet, “Fault Diagnosis Using a Timed Discrete-Event Approach Based on Interval Observers: Application to Sewer Networks”, IEEE Transactions on Systems Man and Cybernetics Part A-Systems and Humans, 40 (5), pp. 900-9116, <doi:10.1109/TSMCA.2010.2052036>, 2010.

- J. Quevedo, V. Puig, G. Cembrano, J. Blanch, J. Aguilar, D. Saporta, G. Benito, M. Hedo and A. Molina, “Validation and reconstruction of flow meter data in the Barcelona water distribution network”, Control Engineering Practice Journal, 18 (6), pp. 640-651, <doi:10.1016/j.conengprac.2010.03.003>, 2010.

Comparteix: